We receive these types of questions via email, phone, and directly from students in the classroom all of the time. Here are some examples:

We receive these types of questions via email, phone, and directly from students in the classroom all of the time. Here are some examples:

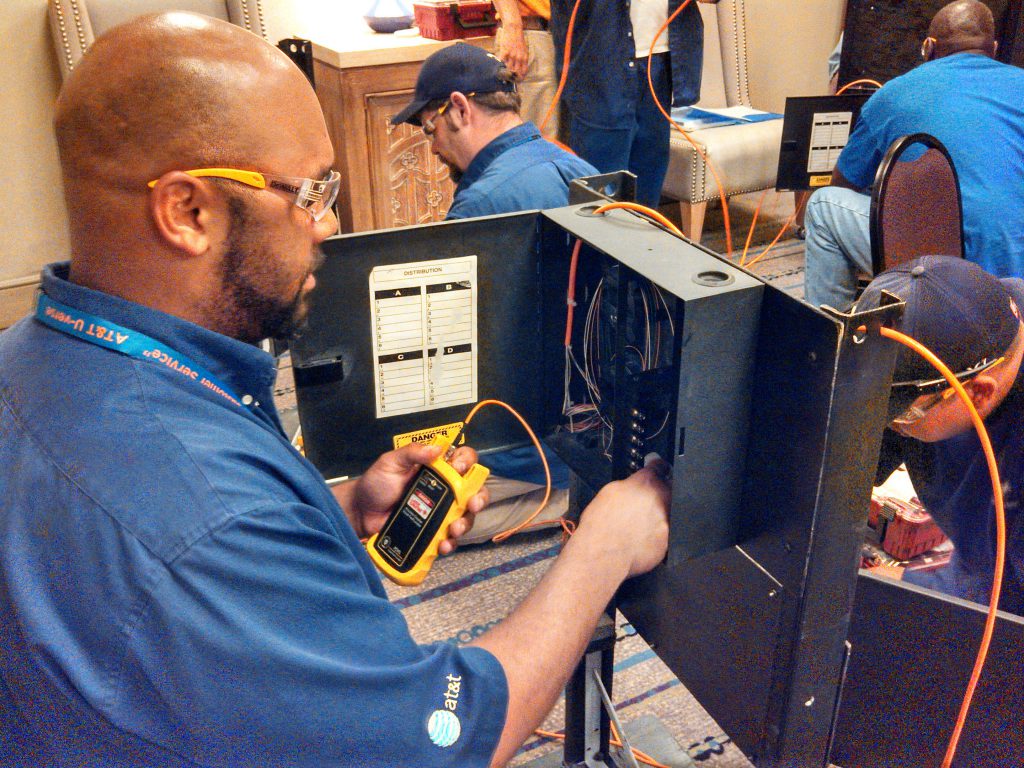

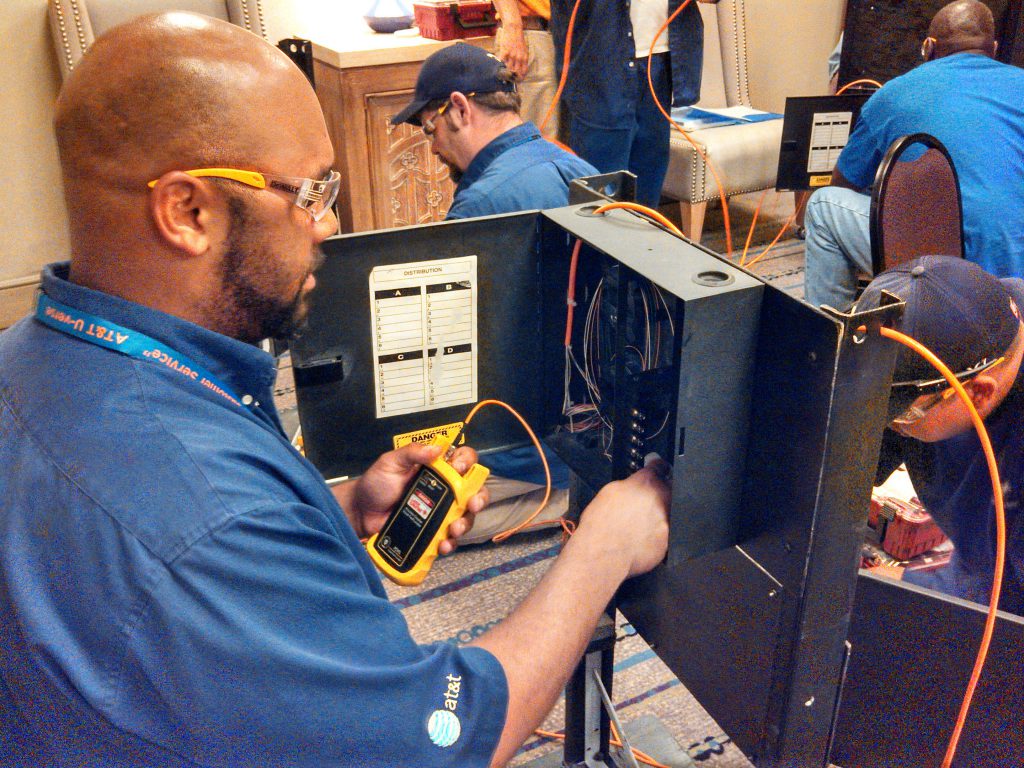

Will I get to build an actual fiber optics network in your classes? YES

Will I be able to install a fiber optics network once I complete your classes? YES

If I only attend the basic, 3-day CFOT course, will that provide enough knowledge for me to go out and get a job? YES, but you will still need company specific OTJ training

What do we do in class? FIND OUT MORE HERE

Leveraging our vast network of campus partners, we train fiber optics technicians nationwide.

Leveraging our vast network of campus partners, we train fiber optics technicians nationwide.

We receive these types of questions via email, phone, and directly from students in the classroom all of the time. Here are some examples:

We receive these types of questions via email, phone, and directly from students in the classroom all of the time. Here are some examples: